offering wide range of Engineering Design

and CAD Drafting Services

Projects

3D Piping Model

Task:

Chemionix Approach & Deliveries:

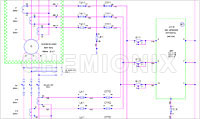

Chemionix Mechanical Engineering & Piping team studied the design generated by our client and first prepared the Piping project specification to be used for this project. The piping specification had details about the piping standard to be used on this project. Right database was selected from our AutoCAD Plant suite software for matching the PPS.

Once our team has selected piping database to be used, skid GA drawings were prepared on structural steel & submitted for approval. Equipment fabrication drawings were requested for proper 3D Equipments modeling.

After approval of 3D Skid Modeling, our piping team thereafter started generation of 3D Piping model for the entire skid. Piping routing were decided for optimum piping length and as per standard design for right routing, with minimum bends, valve operation as right height, maintenance point of view etc..

3D Piping model prepared were regularly discussed with our client for their views and approval. The entire skid modeling was completed in 4 weeks time. Thereafter Piping isometrics were generated along with BOQ for pre fabrications at workshop.

Benefit to our Client:

Chemionix team works with this client on regular basis for generating 3D Piping Skid models, resulting more than $ 20,000 saving per skid for utilizing our Chemionix services.

Chemionix team offered a comprehensive range of Piping Design Services to our international clients.