offering wide range of Engineering Design

and CAD Drafting Services

Projects

3D Piping Design & BOQ Generation

Task:

Hygienic system design along with CIP System design included for our scope of work. Our scope of also including utility lines.

Chemionix Approach & Deliveries:

Chemionix Mechanical Engineering & Piping team studied the complete project requirement from our client. The 3D modeling will be carried out using AutoCAD 3D Plant design Suite modeling system. This has been established as our main 3D design package over many years and thus contains a vast catalogue of European & ASME steelwork, pipework, process equipment, ductwork, cable tray and in-line standard items.

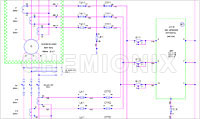

Our mechanical team first studied the entire layout of the project and process requirement. Thereafter our team prepared the P&ID, including the pipe size & pressure drop calculations for this project.

After approval of P&ID, our piping team thereafter started generation of 3D Piping model for the entire project. Piping routing were decided for optimum piping length and as per standard design for right routing, with minimum bends, valve operation as right height, maintenance point of view, proper piping support etc..

Regular interaction with client for approval of the piping routine was conducted and within 8 weeks out team completed the piping modeling of approx 1.5 Kms of total pipings.

After generating the piping model, our team generated complete isometric & Bill of material for this project.

Benefit to our Client:

Chemionix team successfully completed this project in approx 1500 manhours resulting a considerable saving for our client in piping design.

Chemionix team offered a comprehensive Project Consultancy & Engineering Design Services for successfully designing this project.

Have any 3D Piping Design & Detail Engineering Design requirement? Please contact us and we would get back to you within 24 Hours.